When a hot tub pump not working problem appears after refilling the spa, many owners notice that Pump 2 runs normally, while Pump 1 only releases a few bubbles with almost no water flow. This issue is extremely common after the first refill and is usually related to airlocks, flow obstructions, or equipment faults.

This guide provides a professional, EEAT-based breakdown to help technicians, suppliers, and commercial hot tub operators diagnose problems quickly and safely.

Common Causes of Weak Water Flow After Refill

Dirty Filter or Obstructed Circulation Path

A clogged filter cartridge is one of the most frequent causes of weak spa water flow, especially after a refill when debris loosens and enters the system.

Air Valve or Diverter Valve Not Fully Open

Closed or partially closed valves restrict flow and may make Pump 1 appear non-functional. This often causes the pump to push out only bubbles instead of water.

Water Level Too Low

Sufficient water fails to prime the pump, leading to low flow or hot tub pump not working symptoms.

Possible Pump or Piping Failure (Warranty Scope)

If the above items are normal, the issue may involve the wet end, impeller, pump motor, or internal plumbing blockage.

This type of problem should not be self-repaired, as unauthorized disassembly may affect warranty.

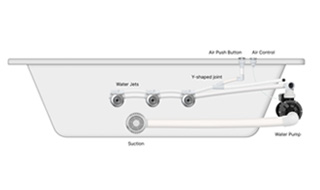

How Airlocks Form and Why They Affect Pumps

Air can become trapped in the pump or plumbing after refilling due to:

Rapid water refill introducing air pockets

Residual chemicals or bubbles in jets

Elevated suction inlets or plumbing high points

Trapped air prevents the pump from creating a proper vacuum, causing low water flow or only bubbles to appear at the outlet. Understanding airlock formation is critical for hot tub troubleshooting.

How to Release an Airlock: Safe and Professional Steps

Airlock is one of the most common reasons for a hot tub pump not working after refill.

Proper air-release procedures restore normal operation in most cases.Step-by-Step Air Release from Pump Wet End

1. Turn off all power to the hot tub before starting.

2. Check whether the wet end has a bleed valve / air release screw.

3. Remove the valve cap (you may need a thin-nose wrench to break the seal).

4. Loosen the air-release screw slowly while holding it firmly to prevent high-pressure water from shooting out.

5. Allow water to flow out for 15 seconds, ensuring no air bubbles remain.

6. Re-tighten the screw and restore power to test the system.

If the pump primes successfully, normal flow should return immediately.

Preventive Maintenance for Pump Longevity

Clean or replace filters every 2–4 weeks for commercial spas.

Check valves, jets, and plumbing for leaks or corrosion regularly.

Avoid running pumps dry to prevent mechanical damage.

Schedule professional inspections at least annually for B2B installations.

When to Stop Troubleshooting and Request Warranty Service

If weak flow continues even after proper air release, cleaning, and valve checks, the issue may involve:

Pump motor failure

Wet-end obstruction

Impeller damage

Internal plumbing blockage

Electrical or controller malfunction

These conditions fall under professional repair and typically meet warranty coverage standards.

Why Commercial Buyers Should Work With Professional Spa Component Suppliers

For

OEMs,

spa brands,

resorts, and

project contractors, stable performance of pumps, jets, and plumbing components is essential.

Working with an experienced B2B supplier ensures:

Consistent quality across large-volume production

Components compliant with CE / UL / RoHS

Engineering support for pump layout & priming design

Faster troubleshooting and replacement cycles

Long-term spare parts supply

If your project requires reliable hot tub pumps, jets, valves, or control systems,

Hydrorelax provides stable B2B supply, OEM customization, and technical support for spas, whirlpools, and hydrotherapy equipment.