Is it worth visiting the factory in person?

If budget allows, absolutely. Nothing is more convincing than seeing the production line yourself. If not, hire a third-party for a factory audit.

How do I balance price and quality?

Think long-term. A high-quality mixing valve reduces returns, after-sales costs, and protects your brand. Cheap valves may save a little upfront, but often cost far more later.

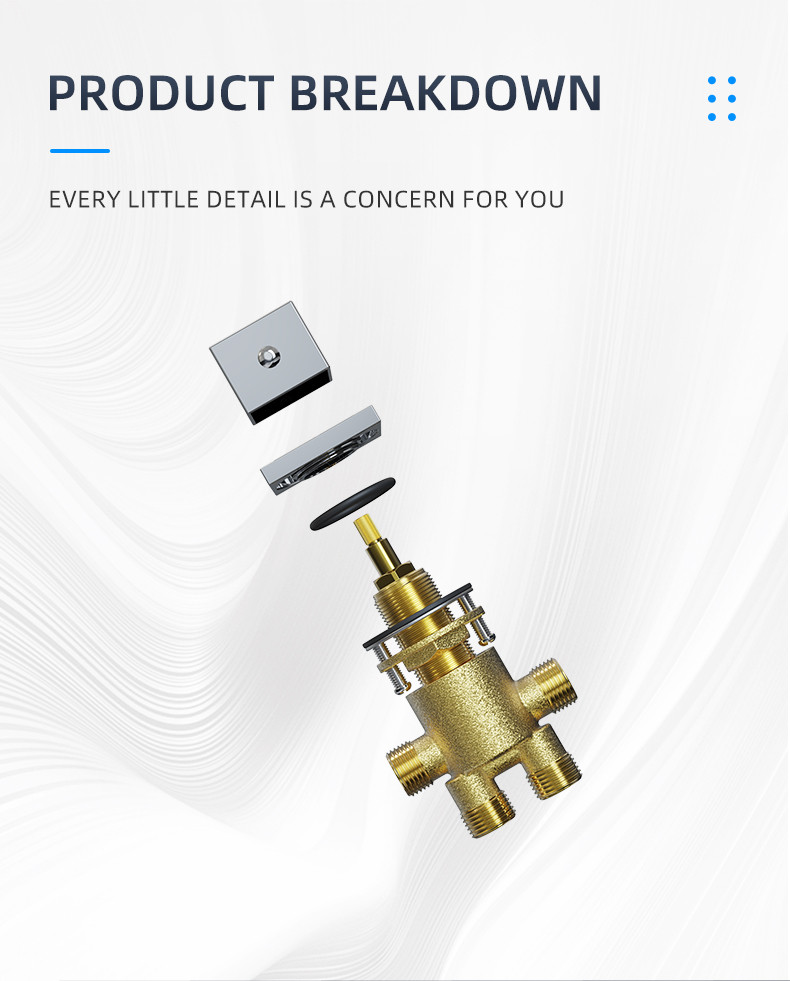

How big is the difference between materials?

Huge. Solid brass valves are durable and fit mid- to high-end markets; stainless steel offers corrosion resistance; zinc alloy is common in low-cost markets, but usually short-lived and unstable.

Do samples represent mass production quality?

Not always. Samples are often the best the factory can make. In mass production, shortcuts may appear. Always arrange a third-party inspection before shipment.

What's the most overlooked detail before ordering?

Packaging. Many focus only on the valve, forgetting that poor packaging can cause damage during transport. Request double-layer protection or custom cartons for long-distance shipment.

What if the bulk order quality is worse than the sample?

If your contract lacks inspection standards and return terms, you're at a disadvantage. Always define materials, testing standards, delivery terms, and remedies for defects clearly in the contract.