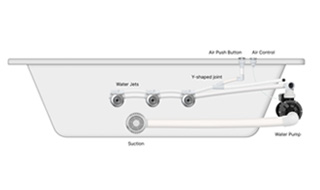

The pump housing is a critical load-bearing component of a bathtub water pump, responsible for supporting the internal impeller and motor while maintaining overall sealing performance.

Reinforced ABS

1.High Impact Resistance: Reinforced ABS offers excellent drop and shock resistance, ensuring the bathtub water pump maintains structural strength and stability during long-term operation, reducing the risk of damage.

2.Excellent Molding Performance: Reinforced ABS is easy to process and suitable for large-scale production, helping to shorten delivery cycles so buyers can receive the required bathtub pumps faster.

3.Smooth Surface Finish: The smooth and even surface of reinforced ABS significantly enhances the overall appearance and perceived quality of the bathtub pump, giving the brand a more professional market impression.

4.Moderate Cost: While ensuring performance, reinforced ABS also provides cost advantages, allowing clients to achieve a balance between performance and price during procurement.

Reinforced PA (Polyamide, commonly known as Nylon)

1.High Mechanical Strength: Reinforced PA offers superior structural strength and pressure resistance, enabling bathtub water pumps to operate under high loads without deformation or damage.

2.Excellent Wear Resistance: Minimizes friction-related wear during long-term operation, extending the service life of the pump housing and critical components while reducing replacement frequency.

3.Outstanding Heat Resistance: Maintains stability and performance even in hot water circulation environments, ensuring the material retains its strength despite temperature fluctuations.

4.Chemical Corrosion Resistance: Effectively resists chlorine, disinfectants, and other common water treatment chemicals, ensuring reliable pump operation over time.

5.High Molding Precision: Provides greater dimensional accuracy, resulting in superior sealing performance that reduces leakage risks and minimizes after-sales issues.