Top 10 Scenarios Where Spa Components Need Replacement

Common Spa Component Failures and Repair Recommendations

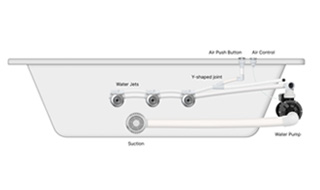

Poor Water Circulation

Excessive Pump Noise

Weak Jet Output

No Bubbles from Air Blower

Heating Failure

Control System Error

Light System Flickering

Abnormal Water Quality

Water Leakage

Core Considerations for Purchasing Spa Component Replacements

Compatibility with the Original System

Certifications and Regulatory Compliance

Material Quality and Durability

How Do Technicians Match Spa Replacement Parts?

Step 1: Collect Original Information

Step 2: Establish Technical Parameter Comparison

Parameter | Original Component Data | Replacement Requirement |

Voltage | 220V | Must be identical |

Power | 1.5kW | Allowable variation ≤ ±10% |

| Connector Size | 2 inch | Thread standard must match |

| Control Protocol | Balboa protocol | Must be compatible |

| Installation | Horizontal | Must be the same |

| Protection Rating | IPX5 | Cannot be lower |