Shower fittings Sourcing from China: Technical Requirements & Product Quality Standards

Shower Accessories Wholesale Sourcing Standards

| Category | Technical Requirements | Product Quality Standards |

| 1.Material: Stainless steel or ABS plastic, ensuring corrosion and oxidation resistance, strong durability. 2.Spray Modes: Multiple spray modes, including rain, massage, and power modes. 3.Flow Control: Must comply with local water-saving standards | 1.Material Standards: Use corrosion-resistant stainless steel or eco-friendly ABS plastic. 2.Spray Performance: The spray head should ensure even water distribution without uneven flow. 3.Durability: Metal surfaces should resist limescale and corrosion. | |

| 1.Material: Stainless steel or copper, offering strong corrosion resistance, suitable for humid environments.

2.Weight Capacity: Each hinge must support at least 40 kg of glass door weight.

3.Opening Angle: Hinges should support at least 90 degrees of opening. | 1.Corrosion Resistance Standards: Materials must pass salt spray tests to ensure rust resistance.

2.Weight Capacity Standards: Tested load must meet actual usage requirements and support the glass door weight over time. | |

| 1.Glass Thickness: 6mm-10mm tempered glass for higher safety.

2.Safety: Must meet tempered glass safety standards, with fragments not being sharp when broken.

3.Surface Treatment: Waterproof coating design to reduce limescale and hard water deposits. | 1.Tempered Glass Standards: Should comply with ISO 12543-2 standards, with no sharp edges when broken.

2.Surface Anti-Stain Treatment: The surface coating should resist limescale and stains. | |

1.Material: Stainless steel or engineering plastics for strength and wear resistance.

2. Weight Capacity: Each set of rollers should support at least 40 kg of glass door weight.

3. Silent Design: Rollers must have a silent function to ensure smooth, quiet operation. | 1.Wear Resistance Standards: Roller surface must pass friction tests to ensure long-term use without damage.

2.Stability Standards: Rollers must operate smoothly without vibration or jamming during door movement. | |

1.Temperature Control: Ensure precise and stable temperature regulation.

2.Water Pressure Adaptability: Must work with various water pressures, including both low and high-pressure environments.

3.Durability: Material should be copper or stainless steel, with strong corrosion and limescale resistance. | 1.Material Standards: Valve cores should be ceramic, copper, or stainless steel for corrosion resistance. Ceramic valve cores are preferred for good sealing, wear resistance, high-temperature resistance, and corrosion resistance.

2.Sealing Standards: Ensure leak-proof design to avoid water leakage. | |

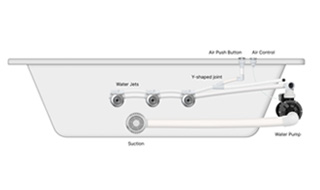

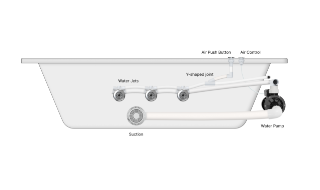

1.Material: Stainless steel or ABS plastic, offering corrosion resistance to prevent limescale buildup.

2.Spray Modes: Should support multiple water flow modes to meet various user preferences.

3.Water Flow Evenness: Ensure even water flow from each nozzle without uneven spraying. | 1.Corrosion Resistance Standards: Use stainless steel material or chrome-plated surfaces to ensure long-term rust resistance.

2.Spray Performance Standards: The water flow should be uniform, and mode switching should be smooth without sticking. | |

1.Material: Silicone or PVC, offering good elasticity and waterproof performance.

2.Size Requirements: Custom-sized according to door gaps for effective sealing.

3.Aging Resistance: Must resist high temperatures and acid-alkali exposure to prevent deformation over time. | 1.Elasticity Standards: The material must provide good elasticity, ensuring long-term usability.

2.Aging Resistance Standards: Should undergo tests for heat resistance and UV resistance to ensure long-term shape retention. | |

1.Material: Stainless steel or aluminum alloy, ensuring strength and corrosion resistance.

2. Design: Ergonomically designed for comfortable grip.

3.Size Requirements: Designed according to bathroom space and user needs. | 1.Corrosion Resistance Standards: Must remain rust-free in humid environments.

2.Comfort Standards: Handle design should be ergonomic and comfortable for prolonged use. | |

1.Material: Moisture-resistant wood, aluminum alloy, or high-strength plastic, ensuring corrosion and water resistance.

2.Design:Adjustable for space-saving.

3.Weight Capacity: Should support at least 120 kg. | 1.Waterproof Standards: Materials should undergo waterproof treatment to prevent mold.

2.Stability Standards: The seat should remain stable during use without wobbling. |

How to Ensure Products Meet Technical and Quality Standards?

Hydrorelax's Final Words