Your choice should depend on brand positioning, project level, and target users:

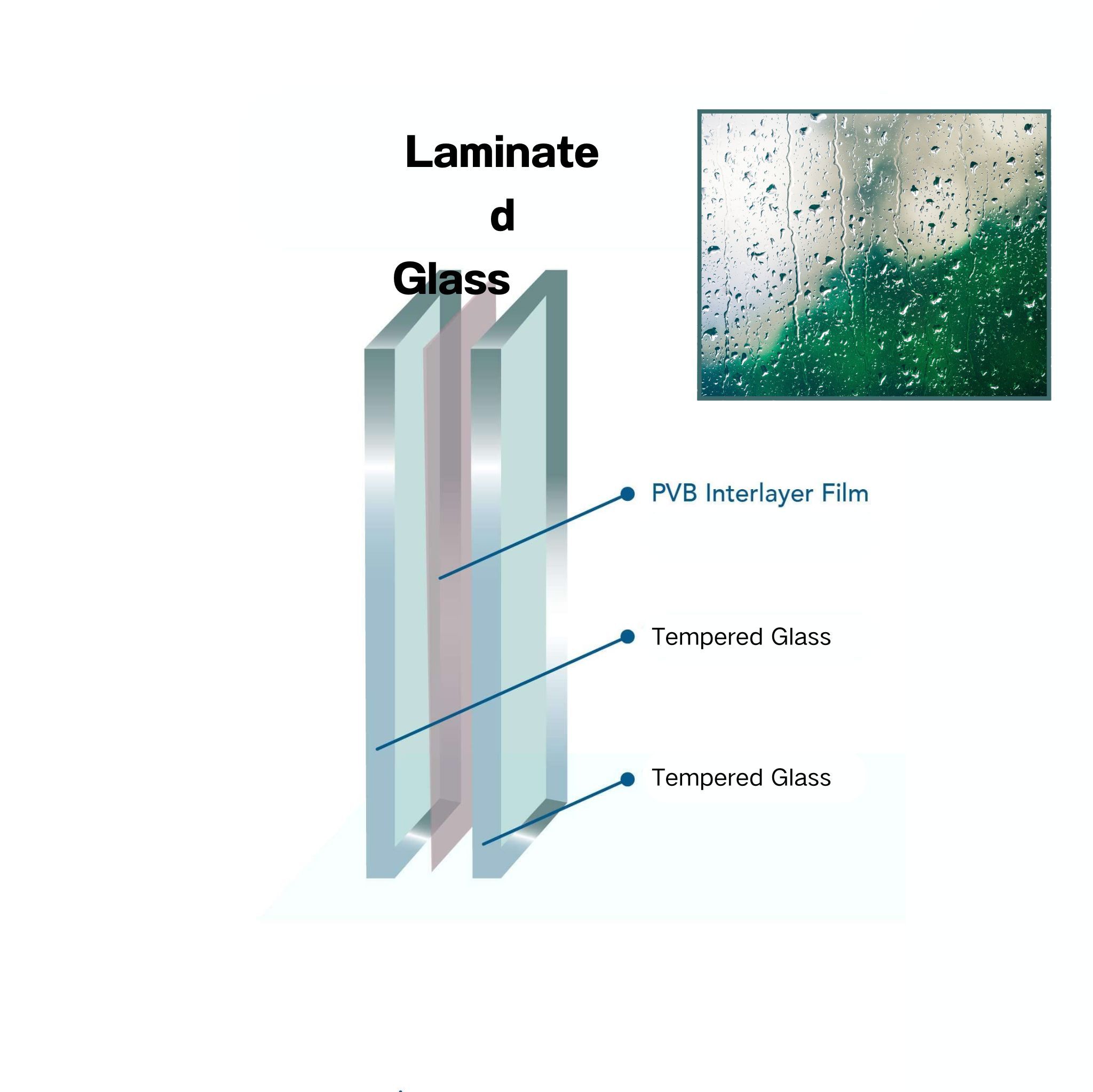

High-end projects: Laminated tempered glass is ideal. It offers the highest safety with minimal long-term maintenance.

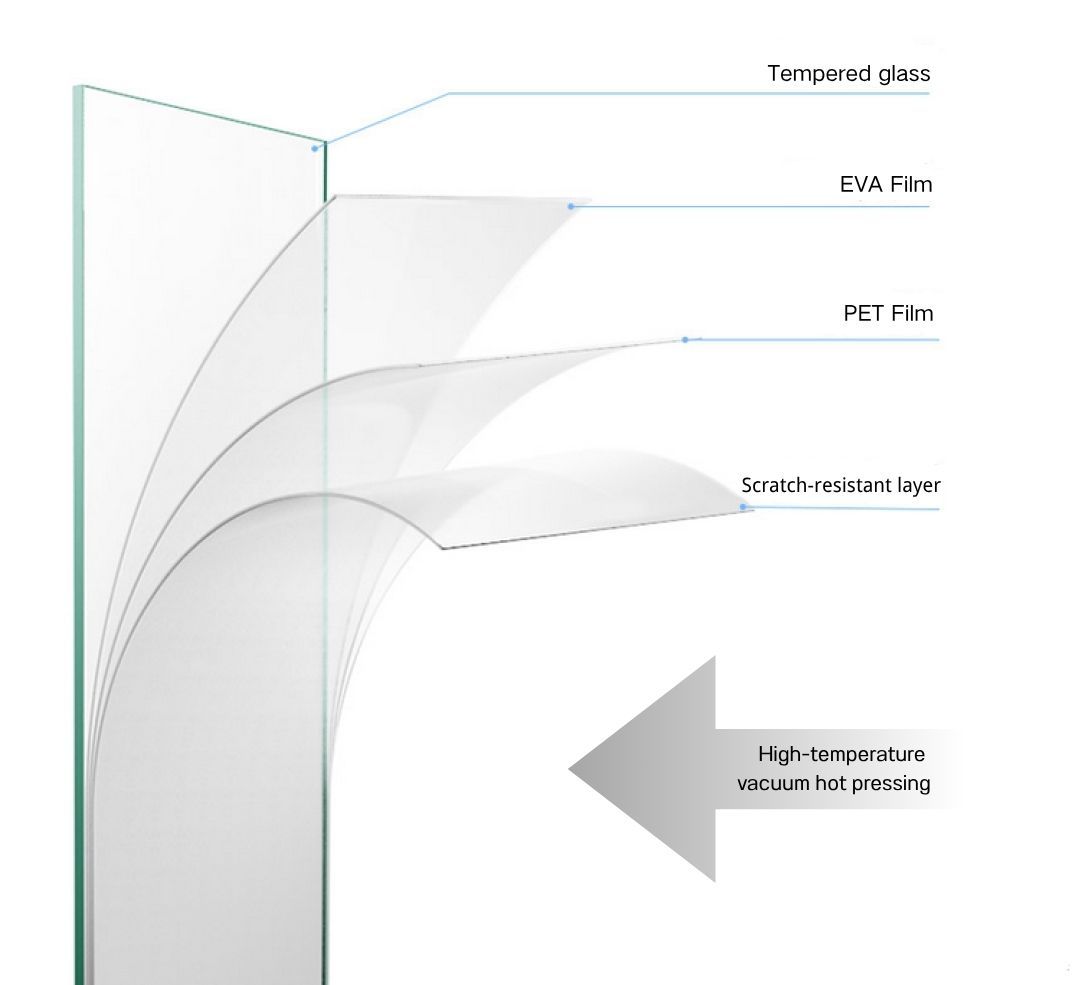

Mid-range projects: Tempered glass with safety film is cost-effective and meets most family safety needs.

Entry-level projects: Use standard tempered glass with strict quality control, proper packaging, and careful installation to reduce stress damage and keep breakage risk low.

How to Safely Transport Shower Glass in Bulk When shipping large quantities of shower glass over long distances, the biggest concern is whether the glass can arrive safely. Though tempered glass is stronger than regular glass, it's still fragile. Uneven pressure or strong vibrations during transit can cause cracks or even breakage.

So how do manufacturers handle this challenge?

Today, most glass factories use standardized reinforced packaging—but thicker cartons alone aren't enough. A proper transport solution usually includes the following:

Special Rack Packaging

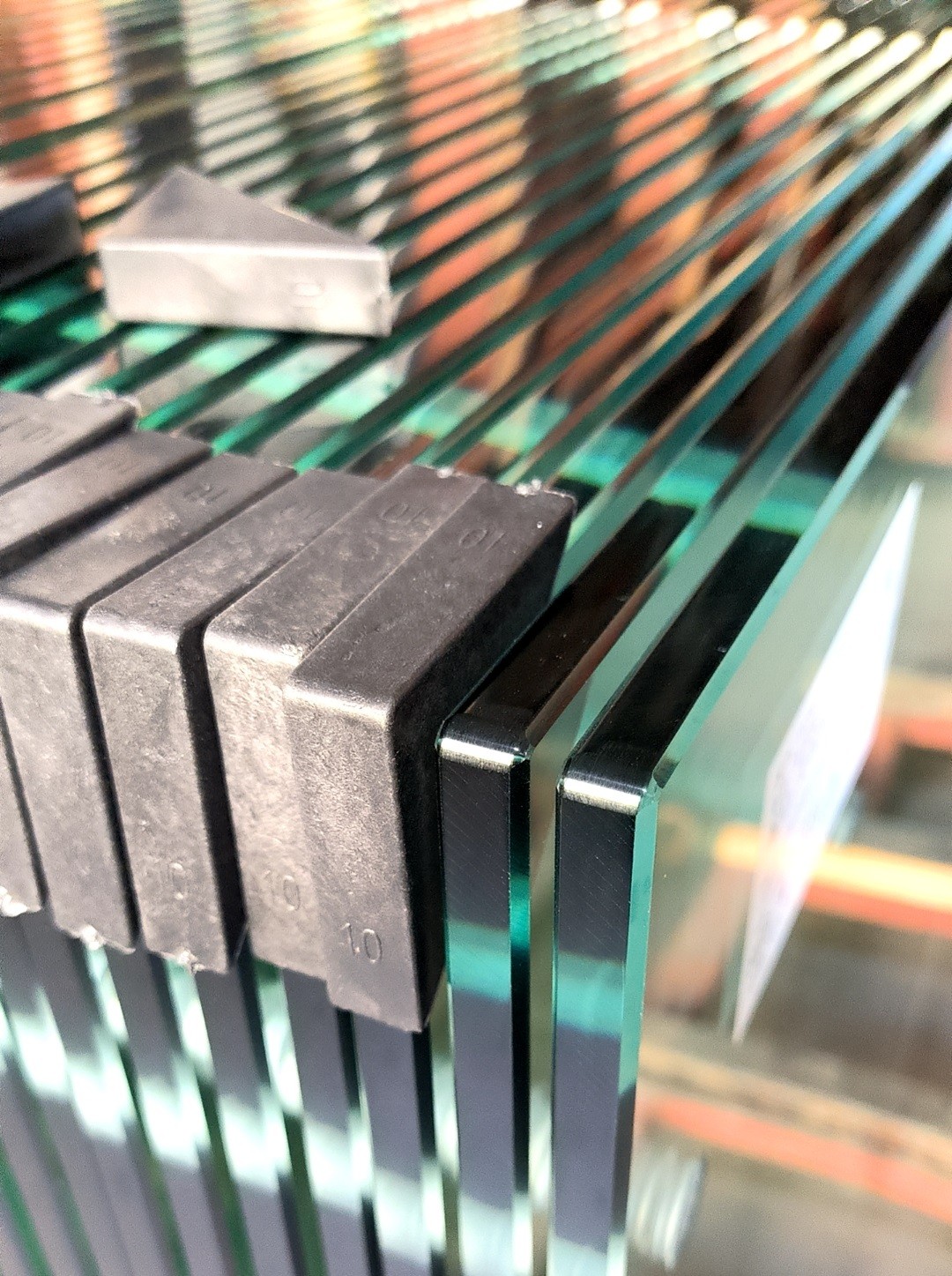

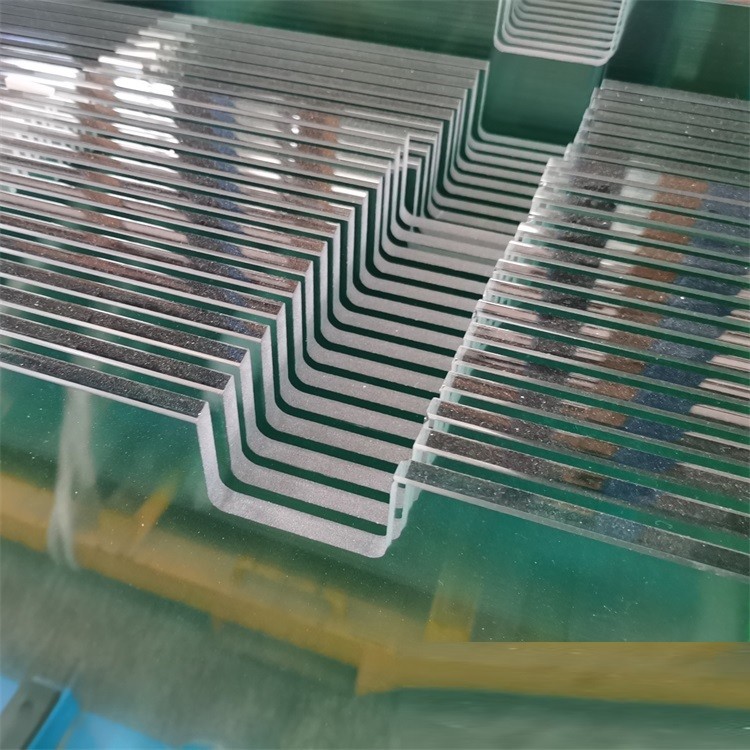

Glass should always be moved standing up, not lying flat. It needs to be placed on A-frame or T-frame racks, which hold it upright and in line with how the vehicle moves. This helps reduce pressure and shaking from bumps on the road.

Foam sheets, plastic film, or other cushioning materials are placed between each glass panel to prevent scratching, friction, or impact during transit.